Ground-Breaking Unit Load Design Tool Minimizes Damage, Maximizes Profit

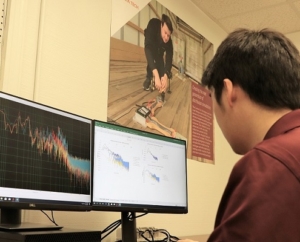

The release of PDS 6.0, the most advanced software tool in the world, considers the interactions between a flexible wood pallet and corrugated boxes. The tool uses world-leading science and modeling that allows pallet designers to prevent cargo damage, while optimizing cost and material efficiency.

“Unit Load for Boxes takes technology normally associated with space flight, race cars, and jet engines and uses it to gain insight into wooden pallet and unit load design,” commented Kristen DeLack, PE, PDS structural engineer.

“We’re excited to take all this know-how and put it into the hands of wooden pallet manufacturers,” added Brent McClendon, NWPCA President and CEO.

Looking Back, Looking Ahead

The Pallet Foundation funded the purchase of multiple large pressure mats in 2011, and multi-year graduate student work at Virginia Tech, to allow NWPCA’s team of engineers to fully visualize the interaction between specific types of containers and the pallet. Further testing in laboratory and in customer’s warehouses on a wide range of containers, pallet designs and support conditions have allowed us to model the interaction for use in PDS.

A Phase I project was designed as a preliminary series of tests of corrugated boxes and pails supported by stringer-class pallets conducted in order to begin to understand the interactions and effects of pallet design. Phase II expanded testing of corrugated boxes on block-class pallets, plastic pails on pallets, and steel drums on pallets.

PDS v6.0 Unit Load for Boxes is just the first installment of system-level unit load design and analysis tools in PDS; drums – plastic pails and sheet goods will follow.

Project Links & Contacts

- Project Lead: Kristen DeLack, PE, PDS Structural Engineer

- Unit Load Primer: An Introduction to PDS 6.1

Presentation of unit load design. An overview of the software tool, background research, and hear some case studies on how it may be used for your customers. (April 2020) - Designing Unit Loads for Corrugated Boxes Part 1 | Part 2 (slides)

Overview of corrugated box information, which will be used as a stepping stone towards full unit load design. Presentation helps you to become more confident when discussing boxes with your customers and stakeholders. (April 2020) - Investigation of the Effect of Corrugated Boxes on the Distribution of Compression Stresses on the Top Surface of Wooden Pallets (June 2019)

- Pallet Design System: Overview and ongoing R&D

Healthy green trees in a forest of old spruce, fir and pine. 123rf.com

Healthy green trees in a forest of old spruce, fir and pine. 123rf.com Pinus radiata blooming in forest springtime. Photo: 123rf.com

Pinus radiata blooming in forest springtime. Photo: 123rf.com